Silicosis, Mining, and Occupational Health in India’s Sandstone Industry

Dec 24th, 2015 | By Absar Ahmad | Category: Featured Articles, Health and Safety, India, Popular Posts

This article summarizes research conducted by the author on the occupational health effects of mining among sandstone miners in Rajasthan, India.

Overview

The increasing demand for metals and minerals to meet the growing requirements of the infrastructure sector has rapidly increased the importance of sandstone mining in India. The state of Rajasthan produces approximately 90% of India’s sandstone, which is used extensively in not only Rajasthan and Northern India, but is also exported to Canada, Japan, and countries in the Middle East. The sandstone is prized for its regular bedding, uniform grain size, suitable nature, and durability.

Sandstone Mining in Rajasthan

Within Rajasthan, the Karauli district has huge deposits of pink colored sandstone used for carving and other decorative purposes. The livelihood of the rural population of this district is mainly agriculture, animal husbandry, and mining with approximately one-third of the population dependent on mining for their livelihood. The district is also characterized by weather extremes with temperatures reaching 48°C in summer and dropping to 4°C in winter.

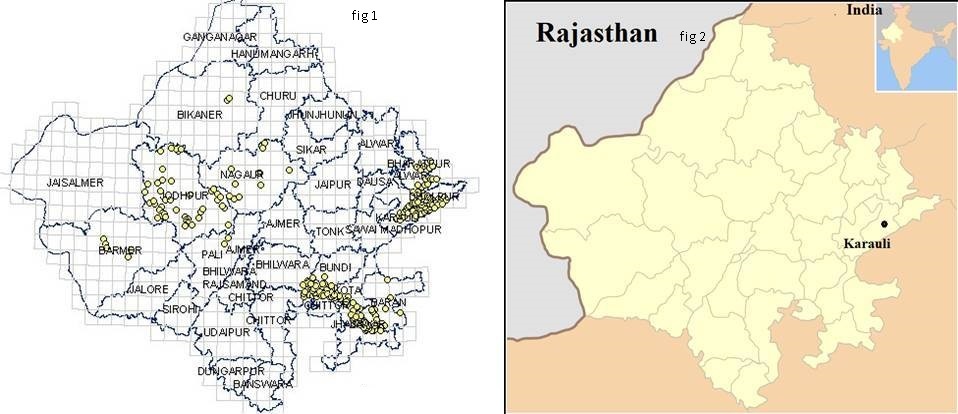

Deposition of Sandstone in Rajasthan (Source: Department of Mines and Geology, Government of Rajasthan) and Study Area Location

Sandstone Workers

Approximately 2.5 million people are employed in more than 30,000 mines in Rajasthan, with more than 71,000 miners working in nearly 1,300 sandstone mines. The mines vary in size, but could employ as few as two to ten people, depending on the size of the stones that are extracted (Ahmad, 2015). However, the actual number of workers in the sector could be higher because the vast majority of mining activity is unorganized, and mine workers are frequently overlooked in government statistics (MLPC, 2005). In the Karauli district, more than 50,000 workers are engaged in the industry.

People who work in the mining industry are mainly members of the marginalized castes. They perform work activities including drilling, blasting, crushing, loading and unloading of sandstone slabs that expose them to elevated levels of silica dust for prolonged periods of time. Although the sandstone can contain up to 70% silica, few technical controls have been implemented to reduce worker exposure to silica dust, and the workers themselves do not usually wear personal protective equipment (PPE) such as respirators or dust masks.

Sandstone Mining Techniques

In this area, the mining process generally starts with the removal of topsoil and sub-soil using excavators (e.g., a rented JCB Machine); in the past, this step was conducted manually. Under the topsoil, usually there is hard, thick-bedded sandstone. A jackhammer is used to drill holes in the stone, and blasting is conducted to break up the sandstone. The beds of sandstone are then split by driving holes using chisels and hammers along the bedding planes at an interval of 5 to 7cm. Afterwards resizing is done, as per the market demand.

Workers are exposed to silica dust in all of these operations. For example, testing shows that the stone crushing operation creates a large amount of dust, which contains silica that ranges between 20 and 70 % by weight (NIMH, 2011).

Mining Tools

Sandstone miners in Rajasthan, India. Note the lack of personal protective equipment.

Health and Safety Hazards of Sandstone Mining

Prolonged exposure to silica dust can cause respiratory diseases such as silicosis and tuberculosis as well as musculoskeletal disorders, and skin and eye diseases. The workers are also exposed to traditional safety hazards associated with mining and hand work (falls from height, loss of limbs, head injuries, strains, cuts, and contusions, hearing loss, etc.), and robbery from armed gangs. They may also be exposed to vectors including snakes, wild animals, and mosquitos.

The photographs below show some of the health impacts associated with sandstone mining.

Worker Suffering from Silicosis

Occupational Health and Safety Impacts

Skin Infections

Government Response

The Rajasthan Environment and Health Administration Board has elected to make an ex gratia payment of approximately US$ 1,500 (Rs. 100,000) to each silicosis-affected person and approximately US$ 4,600 (Rs. 300,000) to the family of a person who dies from silicosis. Payments are made by the Rajasthan Environment and Health Administrative Board (REHAB) after certification of silicosis. A board of doctors with training in pneumoconiosis is appointed, and the board is authorized to issue such certificates.

Conclusion

Sandstone mining is an important economic sector in Rajasthan, providing many people with hard-to-find jobs. Unfortunately, the work activities currently used in this industry expose workers to elevated levels of silica, which can have profound adverse health impacts on the workers. Improvements should be made in the mining and processing operations to reduce workers’ exposure to silica dust. These improvements would likely include technical dust controls and changes in worker awareness and use of appropriate personal protective equipment.

About the Author

Absar Ahmad is a Research Assistant at Giri Institute of Development Studies, Lucknow, India. He is also a Doctoral Student of the International Institute for Population Science, Mumbai, India. This article summarizes fieldwork observations collected by the author as part of the author’s PhD studies. Data collection was conducted from May 2014 to September 2014 in ten sampled villages of the Karauli district in Rajasthan. The information was collected from more than 300 mine workers.

References

Absar Ahmad, “Are the Sandstone Miners Abused in India?” Indian Journal of Community Health 2015; 27, 2: 286-289.

Indian Bureau of Mines (IBM), Indian Minerals Yearbook (Nagpur: Ministry of Mines, Government of India, 2012).

Government of Rajasthan (GOR), Department of Mines and Geology (http://www.dmg-raj.org/)

Greenberg MI, Waksman J, Curtis J., “Silicosis: a review,” Dis Mon 2007 August; 53 (8): 394-416

Leung CC, Yu IT, Chen W., “Silicosis,” Lancet 2012 May 26; 379 (9830): 2008-18

Mine Labour Protection Campaign (MLPC). “The Mining Industry of Rajasthan” in MLPC, eds. MLPC Report. Jodhpur, India: MLPC; 2005

National Institute of Miners Health (NIMH), 2011: “A report: Detection of Silicosis Among Stone Mine Workers from Karauli District,” Nagpur.

Photographs: All photographs were provided by the author, Absar Ahmad.